Improving Looks And Performance With Anodizing

Want to know why anodizing is one of our favorite forms of surface treatment? In this video from Serious Engineering, Gordon Styles breaks down the many benefits of anodizing for aluminum, magnesium and titanium parts. Great looks, corrosion resistance, improved surface hardness – it’s all there and more. Check it out and don’t forget to […]

The Ultimate Guide To Design for Manufacturing

Join us for a comprehensive overview of design for manufacturing, or DFM. It’s a term that’s often used but rarely explained, so today we’re going to explore the details and show why it’s so important for getting the most out of product development. What is Design for Manufacturing? Design for manufacturing (DFM), also known as […]

Surface Textures For Plastic Injection Molding

The surface texture of a plastic part influences much more than how it looks and feels. Surfaces can affect mechanical performance, chemical interactions, electrical resistance or conductivity, friction, corrosion resistance, and many other factors. How are these textures created, and why is this important for your project development goals? Surface textures are imparted to the […]

How To Use DFM To Improve Plastic Injection Molding

We’ve written elsewhere about the importance of design for manufacturing (DFM) analysis in manufacturing. No matter the size of the project, we always recommend using DFM discipline to save time and money while preserving quality. A complete DFM review covers all aspects of product development. In this study, we are going to concentrate specifically on […]

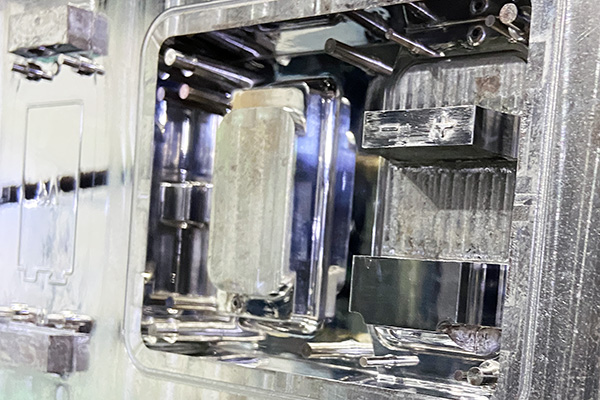

Understanding multi-cavity designs for injection molding efficiency

There are three general categories of plastic injection mold tools that product designers can consider when making finished parts. They each have advantages, largely depending on the intended volumes. Let’s take a closer look at which type might be best for your project. A single cavity plastic injection mold tool is the most basic form […]

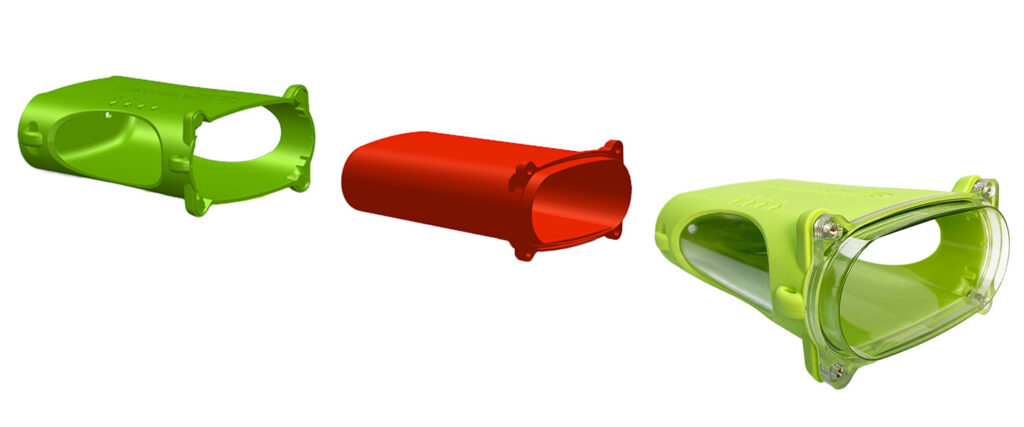

A Complete Guide to Overmolding vs Insert Molding

In this article, we discuss insert molding and overmolding, the advantages of each, and the applications they’re best suited for. We hope these manufacturing insights, along with useful design tips, will help you get great results on your next plastic injection molding project. Navigate to these sections in the article: What is Overmolding? What is […]

Rapid Prototyping With Polyurethane Vacuum Casting

Many plastic injection molding projects start off by first making a series of rapid prototypes. These are used to further refine the look and feel of the part, to test its functionality, and to improve the design before investing in steel injection mold tools. In this video, Gordon Styles explains why rapid prototyping using the […]

Manufacturing Cycle Times and How To Improve Them

Every business has a vested interest in carefully monitoring its productivity, especially in a manufacturing environment where repetitive tasks can be standardized and optimized. The most common metrics used for this purpose are manufacturing cycle times, lead times, and takt times. Progressive companies try to control these factors in order to save money, conserve valuable […]

Color Consistency in Plastic Injection Molding

It’s a big challenge to achieve color consistency for large production runs of plastic injection molded parts. To ensure consistency when molding colors, it’s essential that you have careful process control at every step. It’s important to note that plastic color is highly subjective – subjective in how you see and interpret plastic color. It […]

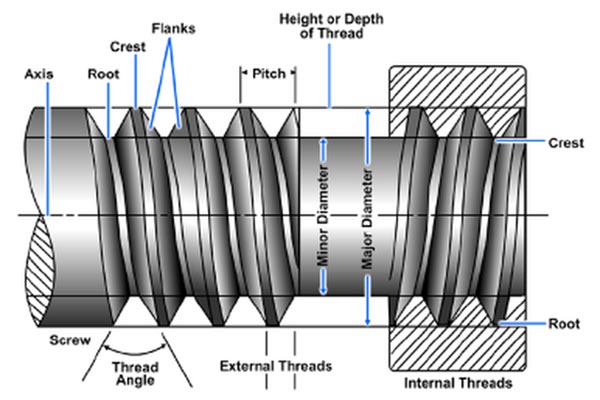

What Every Engineer Needs to Know About Machine Screw Thread Design

Machine screw threads, along with many other kinds of threaded fittings, are used around us every day in millions of applications. In fact, they’re so ubiquitous that they largely go unnoticed by most of us, and to the inexperienced eye they all look and perform pretty much the same. In fact, screw threads are surprisingly […]