Five Rapid Prototyping Solutions For Great Results

Ever since people started making stuff – and then tried to make new and improved stuff – there’s been a need for prototypes. They’re used for design evaluation, testing, certification, proof-of-concept, crowdfunding campaigns and as bridges to full production. If you need high-quality rapid prototypes, may we suggest you consider these 5 well-established and mature […]

The Top 4 Surface Treatments for Production Tooling

TiN coating on mold tool. Image courtesy of prirev.com.All manufacturing tools are subject to incredibly harsh working conditions and must withstand a lot of wear and tear. Tools used for plastic injection molding are no exception, where corrosive resins and abrasive fibers, injected under tons of pressure, can quickly destroy soft or untreated metal. If […]

The 5 Most Common Methods for Applying Textures to Injection Molding Tools

Surface textures and patterns applied to plastic injection molded parts are becoming more sophisticated and complex. These advancements are exciting because they offer so many new design options for product developers and engineers. But before a finished part can be made, the injection molding tool must first be carefully manufactured. So how do manufacturers apply […]

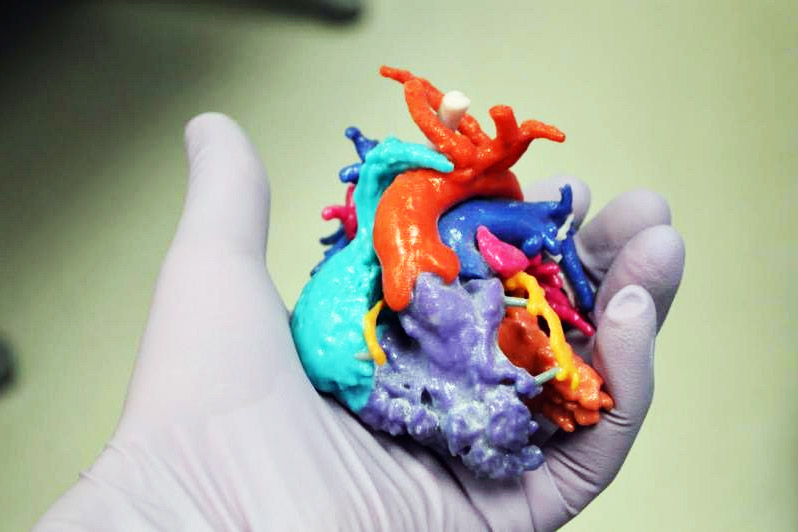

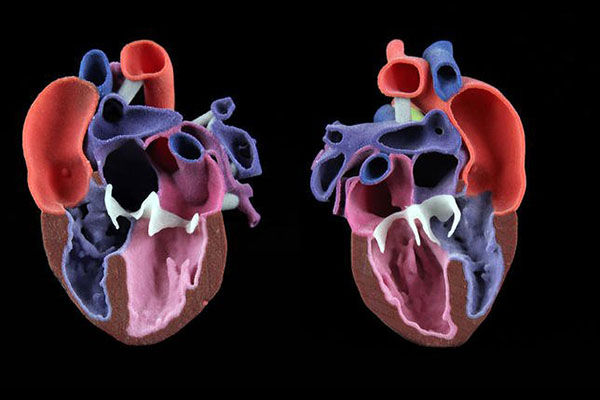

Additive Manufacturing for Medical Applications

The use of additive manufacturing applications is on the rise, with the market value expected to increase from $6 billion in 2017 to nearly $26 billion by 2022. The advantage of additive manufacturing comes from creating complex structures that vary in complexity, customization, lightweight, strength, and speed. As additive manufacturing for medical devices continues to […]

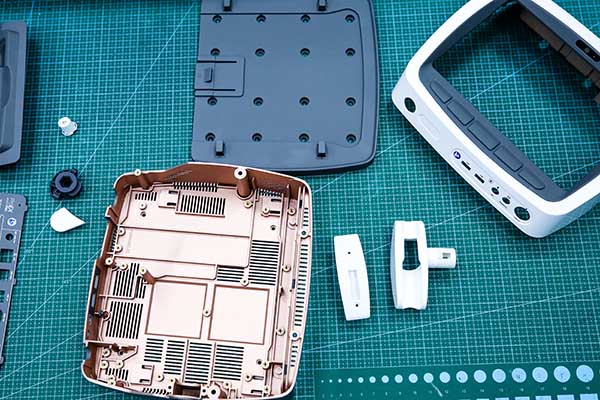

Top 7 Advantages to Using CNC Machining for Rapid Prototyping

Rapid prototyping means building a physical model of a new product design as quickly and as economically as possible. Some prototypes will be used merely as cosmetic mock-ups or scale models, while others must meet more demanding performance criteria. Prototypes are used for testing, design iteration and to improve overall performance through gradual refinements. For […]

Why Small Dimensions Are A Big Deal in Manufacturing

Precision manufacturing means consistently producing parts that have dimensions with very fine tolerances, usually measured in microns or 10-6 meters. This is entirely possible when using good CAD/CAM digital equipment and modern, high-speed cutting tools. But there are some other practical considerations on the small scale that go beyond the equipment used, because all materials […]

Why Micro Molding Is Ideal for Small Medical Products

Micro molding is a specialized form of plastic injection molding for making parts on a very small scale. How small? Finished components can easily weigh less than 1 g and measure smaller than 1 mm in cross-section. How can this help you? To understand the many benefits of micro molding for small plastic parts, we […]

Six Reasons To Use Vacuum Casting For Medical Products

Virtually all new products intended for the medical industry start out as prototypes. Prototypes are used for proof-of-concept, engineering testing, certifications, benchmarking and as design models. And for this purpose, vacuum casting is the ideal rapid prototyping service when preparing a product for high volume production, especially with plastic injection molding. Because injection molding requires […]

4 Benefits of Plastic Injection Molding for Medical Devices: How Injection Molded Medical Devices Can Help You

Every day around the world in hospitals and clinics, research laboratories, and universities, numerous plastic products are used for medical parts, devices, appliances, and support equipment. The variety of applications for injection-molded devices is almost limitless. This is due to the fact that plastic injection molding is perfect for making high volumes of identical, close-tolerance […]

The 5 Major Benefits of Using 3D Printing for Medical Devices

Additive manufacturing in metal or plastic has some limitations as a high-volume production method. It does not, and maybe never will, compete with conventional manufacturing like plastic injection molding or CNC machining when it comes to ultimate speed and efficiency. But that’s ok because 3D printing is a perfect solution for quickly making models and […]