Anodized Aluminum Colors: Understanding Color Matching

A Walkthrough of the Aluminum Anodizing and Color Matching Process Anodizing is a great way to put an attractive and physically durable finish on aluminum parts. Anodizing improves corrosion resistance, surface hardness, prevents scratching and is an ideal foundation for painting, glue or powder coating. There are many challenges when trying to match colors on […]

4 Great Ways to Find The Right Chinese Supplier

China is a great choice for product developers searching for new manufacturing suppliers. Along with its modern infrastructure, the Chinese industrial sector enjoys high levels of government support and there are factories able to produce almost any product you can imagine. However, not all suppliers are the same. It’s essential to find the right one […]

Is Aluminum Tooling Dead?

As part of our ongoing mission to improve the quality of our rapid tooling service, the team at Star Rapid has moved away from using aluminum for plastic injection mold tools and we now use steel such as P20, NAK80, S136 and H13 instead. We did this because we’ve found that there are too few […]

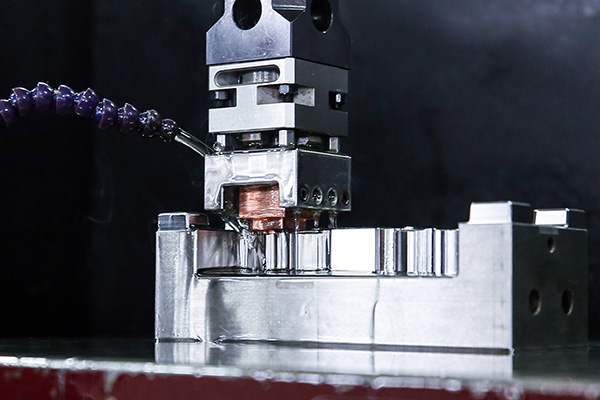

CNC Milling in China

At Star Rapid we make rapid prototypes, low-volume production parts and custom tools at our manufacturing facility in China. Many of these projects rely on the use of CNC milling. CNC milling is one of the foundations of modern machining. Star has invested in dozens of imported multi-axis CNC mills and lathes that allow us […]

Product Applications Help You Find the Plastic That’s Right for You

When developing a new product, there are so many different types of plastic available to use. Choosing the right one depends on application-specific criteria. In our experience, developers should consider if the plastic material is food safe, impact resistant, flexible, engineering grade, fire retardant or biocompatible. The below are our recommendations on the most common […]

6 Things To Prepare When Requesting a Quote

When developing a product you need fast and accurate quotations from your supplier to get your project started and to understand the cost and lead times involved. To ensure you get an accurate quote, manufacturing suppliers will need information from you to make sure they produce exactly the parts you expect and provide an accurate […]

Overmolding for Vacuum Casting Prototypes

Polyurethane vacuum casting is a great way to make quick-turnaround rapid prototypes. Solid master patterns are used to cast soft silicone rubber molds, and these molds yield up to twenty copies of the original with excellent surface finishes and only a minimal investment in raw materials. There is also another advantage to vacuum casting that […]

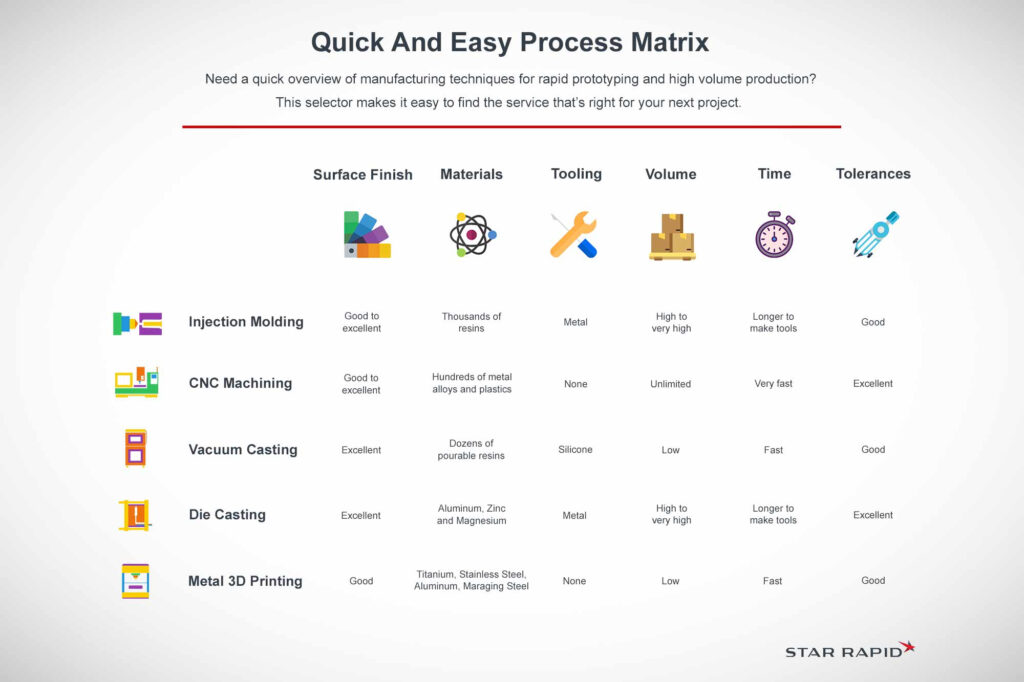

Reference Chart for Rapid Prototyping and Low Volume Manufacturing

If you’re trying to bring a new product idea to market, there may be more than one manufacturing method that will suit your needs. Each of these processes used at Star Rapid has advantages for lead time, precision, start-up costs, volume and more. Plastic Injection Molding 1~4 weeks to make injection molding tools and dies […]

Benefits of Vacuum Casting for Rapid Prototypes

If you’re wondering what the most cost-effective way to make any prototype is, it may be time to set your sights on vacuum casting. Vacuum casting—sometimes referred to as urethane casting or polyurethane casting—was first developed in Europe in the 1960s and has since become one of the most widely used techniques for the development […]

What Makes a Great Paint Job

When people think of paint, they tend to think of it in a general sense. They often picture a smooth liquid substance that—once applied to a surface—can bring walls, buildings, and furniture to life. The definition doesn’t do justice to the sophisticated chemistry underlying modern coating technology. At Star Rapid, we use a variety of […]