Rapid Tool Changes With An Induction Shrink Fit System

Star Rapid has a growing list of advanced equipment for improving efficiency, shortening lead times and lowering costs. The Gühring GSS 2000 induction shrink fit system is the perfect accompaniment to our multi-axis CNC machining services, making tool changes more rapid, reliable and accurate. How does an induction shrink fit system work? An induction shrink fit […]

Industrial Equipment News: What tolerances can you expect when manufacturing prototypes?

For prototypes and low-volume production, one of the ways to ensure quick turnaround on your parts is by keeping designs simple and not over-engineering them

Growing a Culture of Quality in China

What does it take to employ world-class quality standards when running your own business out of China?

Successful Product Development: The Importance of Proof of Concept

You will be told that you need to prototype your product to make sure that it works. But before you dive into the world of rapid prototyping, there’s one step that quite a few startups miss out on: creating a proof of concept.

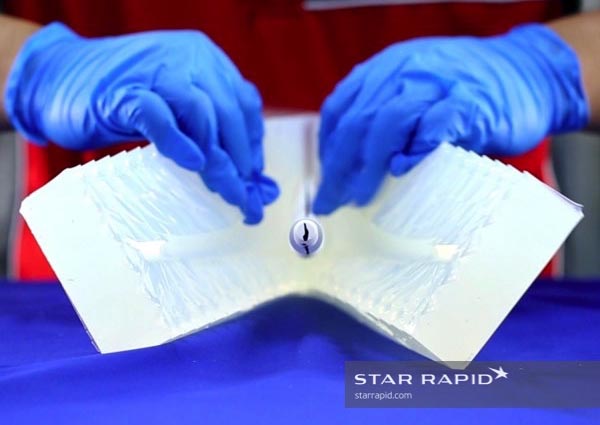

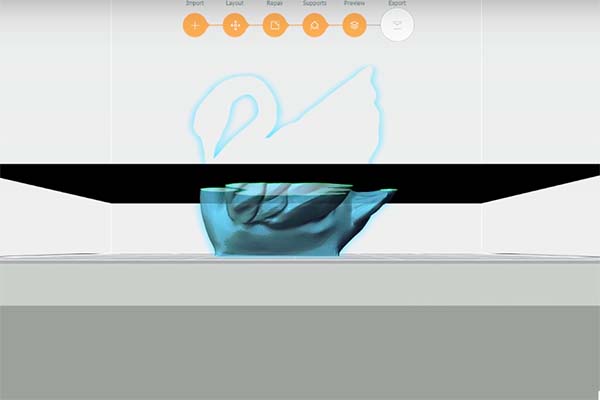

Is SLA The Right 3D Printing Solution For You?

3D printing in plastic began more than 35 years ago with the invention of stereolithography (SLA). Although there have been many developments in additive manufacturing since then, SLA is still a popular process for rapid prototyping. First let’s take a look at how the technology works, and then see why it may be a good option […]

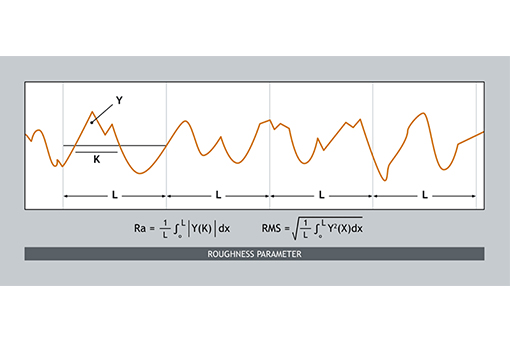

Understanding Surface Roughness for Product Development

Surface roughness is often described by the term Ra but many of our clients are unsure about what this means, how it’s measured and why it’s important to their product’s designs. So here we’d like to remove any mystery so you’re better able to specify exactly the type of surface roughness you want and need […]

What are the Top Passivation Techniques?

What Does Passivation Mean? Passivation means to alter the chemical structure of a metal at or just below the surface, so that it’s more stable and doesn’t want to react with other elements in an undesirable way. There are several different manufacturing processes that we routinely use to passivate the surface of a part. The […]

How 3D Printing Can Preserve And Restore The Past

3D scanning in combination with 3D printing now makes it possible to create all sorts of physical objects. This technology has become so advanced that it helps to preserve or restore historic artifacts that no longer exist. Let’s take a closer look at how 3D printing is currently being used to help protect and even recreate the vanishing […]

7 Techniques For Finishing A Metal Surface

All metal prototyping and CNC machined components will leave behind a pattern of characteristic scratches on the workpiece. These are caused by the type of cutting tool, how sharp it is and the material it’s made from. In some cases these scratches can be ignored but usually to make a truly “finished” part one or more […]

The Top 4 Benefits of Low-Volume Manufacturing

The world of product design continues to undergo some fundamental and even revolutionary changes. Product lifespans are getting shorter and so is the expected time to market. As a result, product developers are moving away from mass production and towards the world of low-volume manufacturing. What Is Low-Volume Manufacturing? Low-volume manufacturing involves the production of 50 to 100,000 parts, acting […]