Improving CNC Machined Parts with Thin Film Coatings

One reason Star Rapid recently partnered with Guhring tools of Germany is because of their proven technology in applying thin film coatings to their cutting tools. Let’s look at why these thin films are so important to tool performance and how this translates into improved quality for the CNC machined parts we make for you. […]

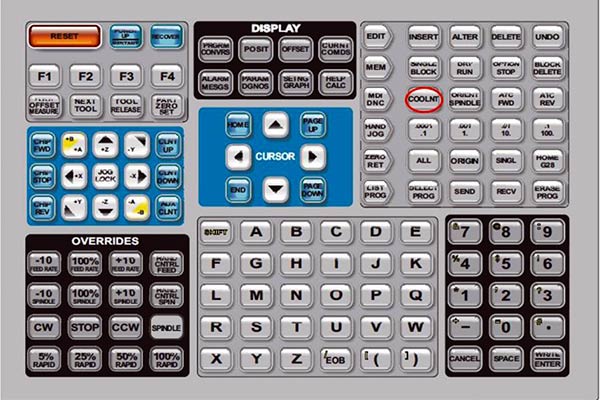

How is G-Code Used to Make CNC Machined Parts?

What is G-Code? G-code is a generic term for a programming language used to instruct a numerically-controlled machine tool. It controls all aspects of machine movement including spindle speed, the tool path, how fast to move and where to locate itself in a multi-axis space. Why is it Important to Verify the G-Code? Complex shapes […]

Star Rapid Partners With German Tool Supplier Guhring

At Star, we are always looking for ways to improve speed and quality. One way we’ve done this is by partnering with the tool company Guhring to ensure that we provide only the finest tools when making CNC machined parts and rapid prototypes. Guhring is a German manufacturer of carbide and PCD cutting tools like […]

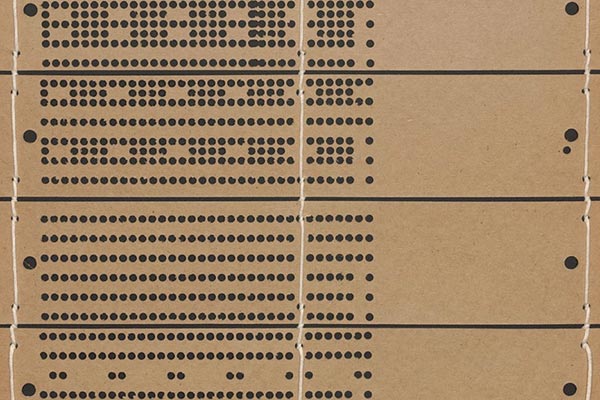

6 Early Inventions in the History of CNC Machining

All CNC machines, regardless of their size or complexity, make use of the same few technical innovations – some more than one-hundred years old. By tracing the history of these innovations we can follow the trends that led to the development of the first numerically controlled machines in the late 1940s and ultimately to the […]

Understanding Accuracy, Precision and Tolerance To Improve Product Design

Computer Aided Design (CAD) software is now the default tool for drawing perfectly rendered objects on a computer screen, which are then transferred to a manufacturer to make the actual part. But there’s a danger in thinking that anything that can be designed can just as easily be made. Software programs are capable of drawing […]

New Machines Increase Our CNC Machining Capacity

With the arrival of six new Haas machining centers (four VF 2 SS and two DT-1), we now have fourteen additions to the CNC manufacturing workshop this year alone, with more on the way. Three machines will be dedicated to high-speed milling, while two more will be used for drilling and tapping. These complement the […]

Encouraging Young Graduates To Get Excited About Manufacturing

On Thursday July 6th, a group of 7 recent graduates from the Zhongshan Polytechnic University came to visit Star Rapid to understand more about manufacturing in a high-tech environment.

Rapid Tool Changes With An Induction Shrink Fit System

Star Rapid has a growing list of advanced equipment for improving efficiency, shortening lead times and lowering costs. The Gühring GSS 2000 induction shrink fit system is the perfect accompaniment to our multi-axis CNC machining services, making tool changes more rapid, reliable and accurate. How does an induction shrink fit system work? An induction shrink fit […]

How To Save Money On Your Next CNC Project

There are many ways to improve your design drawings to make them faster, easier and cheaper to CNC machine while maintaining quality. One way is by understanding and optimizing your specifications for corner radii. Sometimes a few minor changes to your corner radii can make a big difference in price and delivery times. Here is […]

How Can You Prevent Your Product From Being a Failure?

There’s a plethora of reasons for why new products fail. But there are different steps you can take to minimize the risks when developing a new product.