The Top 5 Design Tips for Medical Products

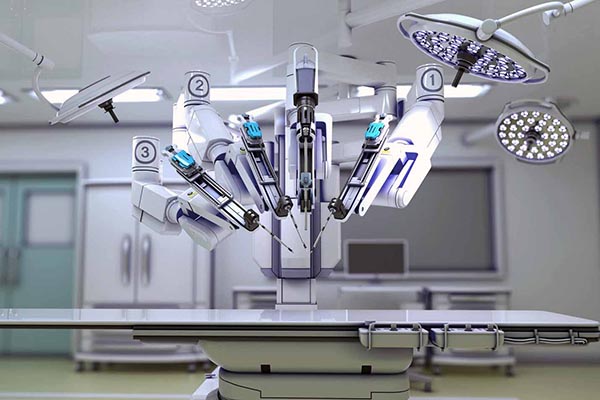

As we all know, devices used in medicine and healthcare must meet the highest standards of performance and reliability. This is as it should be, but medical products are more than merely practical tools or appliances. Although there are many different types and applications, to the greatest degree possible they also must satisfy human emotional […]

The Six Benefits of ISO 13485:2016 For Product Developers

What is ISO 13485:2016? ISO 13485:2016 is a quality system management standard. It’s similar to ISO 9001, but has a few more stipulations to help companies meet the more specialized demands that come with making medical components and healthcare related products. This standard is often referred to when medical and related products are submitted for […]

Why Micro Molding Is Ideal for Small Medical Products

Micro molding is a specialized form of plastic injection molding for making parts on a very small scale. How small? Finished components can easily weigh less than 1 g and measure smaller than 1 mm in cross-section. How can this help you? To understand the many benefits of micro molding for small plastic parts, we […]

Six Reasons To Use Vacuum Casting For Medical Products

Virtually all new products intended for the medical industry start out as prototypes. Prototypes are used for proof-of-concept, engineering testing, certifications, benchmarking and as design models. And for this purpose, vacuum casting is the ideal rapid prototyping service when preparing a product for high volume production, especially with plastic injection molding. Because injection molding requires […]

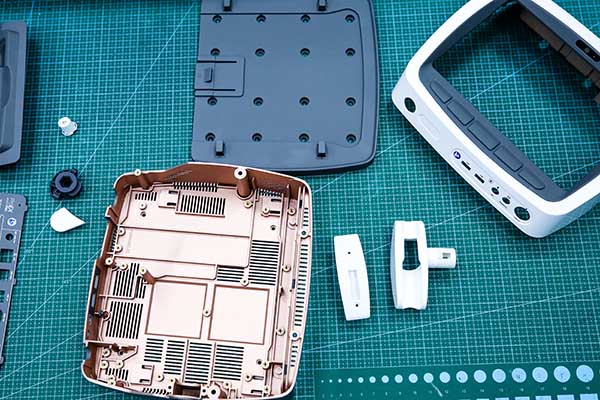

4 Benefits of Plastic Injection Molding for Medical Devices: How Injection Molded Medical Devices Can Help You

Every day around the world in hospitals and clinics, research laboratories, and universities, numerous plastic products are used for medical parts, devices, appliances, and support equipment. The variety of applications for injection-molded devices is almost limitless. This is due to the fact that plastic injection molding is perfect for making high volumes of identical, close-tolerance […]

CNC Medical Machining: Benefits of CNC Machining for Medical Industry Products and Parts

CNC machining, in its many forms, is one of the most versatile of all conventional manufacturing processes. The versatility of cnc machining extends to the types of parts that can be made, the material from which they are made, and the volumes produced. Using conventional CNC milling and turning, parts can be made for medical […]

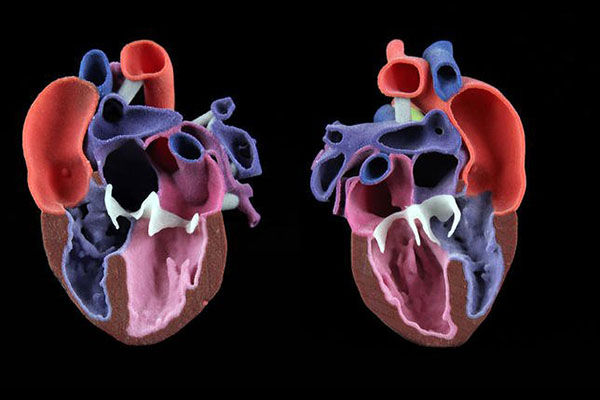

The 5 Major Benefits of Using 3D Printing for Medical Devices

Additive manufacturing in metal or plastic has some limitations as a high-volume production method. It does not, and maybe never will, compete with conventional manufacturing like plastic injection molding or CNC machining when it comes to ultimate speed and efficiency. But that’s ok because 3D printing is a perfect solution for quickly making models and […]

How To Choose the Right Plastic Resins for Medical Products

Plastic resins are used to make medical products of all types. This is because it’s inexpensive, lightweight, strong and durable. Plastic injection molding allows for many design options and it’s relatively easy to modify them as needed. Some resins are appropriate for single-use applications and can also be recycled. But not every type of plastic is […]