Industrial Equipment News: “4 Facts on Custom Colors In Injection Molding”

Getting the exact color you want on your next plastic injection molding project requires a practical understanding of how color is analyzed and prepared

Custom Colors in Injection Molding – What You Need To Know

Let’s say you’ve got a great new idea for a plastic product and you’ve found a manufacturing partner to help you make it. You don’t need a lot of parts to start out with, but you do need that special custom color which is really going to make the whole thing come alive. Just show […]

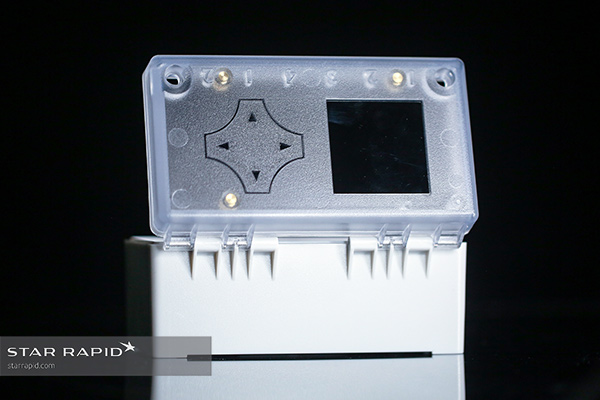

We’re Expanding! New Equipment and Software.

The recent rebranding of Star Prototype to Star Rapid is much more than a name change and a fresh coat of paint. Our rebranding also coincides with an expansion of our 60,000 square foot facility and a significant investment of more than US $2.5 million in cutting-edge manufacturing equipment and management software. Here are some things you […]

How To Control Weld Lines In Plastic Injected Molded Parts

Plastic injection moulding is the industry’s most common way to manufacture parts. This production method is particularly popular when manufacturing in large quantities. Weld lines are a common imperfection to be found in most plastic injected molded parts. They are the result of fundamental physical effects taking place inside of the mold tool cavity. Although they […]

How Wires, Cables And Connectors Work

Some of the custom rapid prototypes and low-volume manufactured parts we make aren’t finished products when they leave our facilities. Many still need to be combined with wires, cables, pcb controllers and other assorted electrical hardware to make a complete product solution. We don’t specialize in this area, so we consulted with Swiss electrical engineer […]

How to Use the PolyMax Gun to Identify Plastic

Are You Getting The Plastic You Asked For? With so many different types of plastic on the market, being able to correctly identify each one is critical for getting the right results when manufacturing a new product. But what’s the best way to identify plastic material accurately and repeatably, when so many kinds look and feel the same […]

Vitrimers May Replace Plastics As We Know Them

A truly revolutionary new class of material successfully combines the best attributes of thermoforming and thermosetting plastic. This could change the way we make rubber ducks, jumbo planes and everything in between. It might also greatly effect and improve our impact on the environment. What Are The Most Common Plastics? Polymers, generically called plastic, used […]

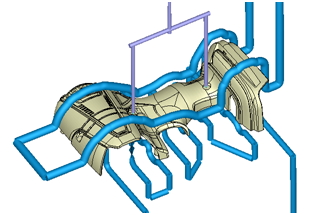

Advanced Methods For Making Better Mold Tools

Recent innovations in tooling construction with conformal heating and cooling channels open up exciting new possibilities for part designs with improved throughput and lower costs. Product developers and engineers now have access to new techniques made possible by additive manufacturing which promise enormous benefits in productivity, cost savings and finished part quality. Let’s take a look […]

AddSub: The Ideal 3D Metal Printing Solution

There’s been a lot of talk zooming around lately about the wonders of additive manufacturing and 3D metal printing, but along with that a lot of misunderstandings about the benefits of this technology for product designers, tooling engineers and prototype makers. We want to take a moment here to clarify some of the confusion and […]

Plastic Injection Material For Dummies

No, not plastics to make dummies out of, although you could do that. We want to talk about the kinds of plastics you need for the plastic injection process, and how to make sense of the dizzying array of choices out there. Plastic injection molding is, by far, the most popular industrial technique for making […]