The Ultimate Guide To Design for Manufacturing

Join us for a comprehensive overview of design for manufacturing, or DFM. It’s a term that’s often used but rarely explained, so today we’re going to explore the details and show why it’s so important for getting the most out of product development. What is Design for Manufacturing? Design for manufacturing (DFM), also known as […]

How To Choose the Right Plastic Resins for Medical Products

Plastic resins are used to make medical products of all types. This is because it’s inexpensive, lightweight, strong and durable. Plastic injection molding allows for many design options and it’s relatively easy to modify them as needed. Some resins are appropriate for single-use applications and can also be recycled. But not every type of plastic is […]

Understanding FDA Medical Classifications

The Food and Drug Administration in the United States is responsible for the classification of all products that are used in medicine and healthcare. As with regulators in other countries, such as the European Medicines Agency, they must categorize a vast array of goods that, in one way or another, interact with human health. These […]

6 Product Design Tips from Robots

You may never have heard of Mr. Joe Jones, but he’s the inventor of one of the most successful commercial robots ever made – the Roomba. Mr. Jones, a graduate of MIT, has experience designing hundreds of robots and he’s identified a few key precepts that apply to good engineering and design best practices, not […]

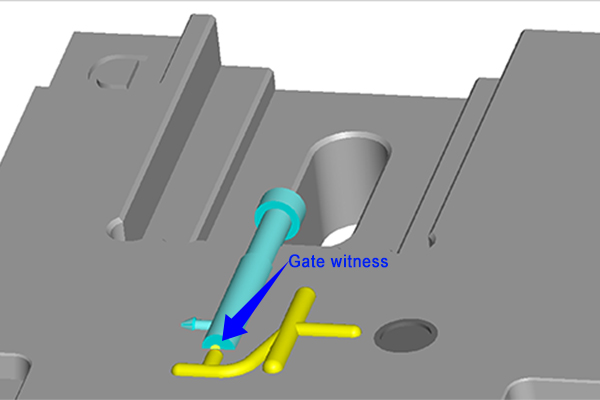

Micro Machines are a Big Win for Plastic Injection Molding

We’re excited to announce that we’ve expanded our capabilities in plastic injection molding with the recent addition of two new Babyplast horizontal micro molding machines. This demonstrates our commitment to providing the most agile manufacturing services for customers who need small, precision plastic parts. Let’s look more closely at the advantages of micro molding and […]

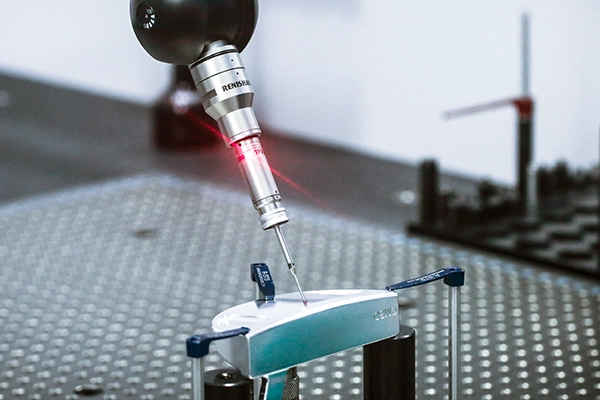

Tips For Verifying A Supplier Remotely

As a product developer, you may be wondering how you can verify the integrity of your supply chain during these uncertain times, with so many quarantine and travel restrictions in place. While it may be difficult or even impossible to visit a supplier in person, there are still some things you can do to help […]

Controlling The 6 Factors That Affect Manufacturing Costs

Product developers need to have a clear and complete understanding of the expenses involved in making their products before they commit their resources. Some costs are relatively fixed and therefore predictable. These fixed costs can be carried by the manufacturer, the customer, or both. Other costs are more variable and depend on a number of […]

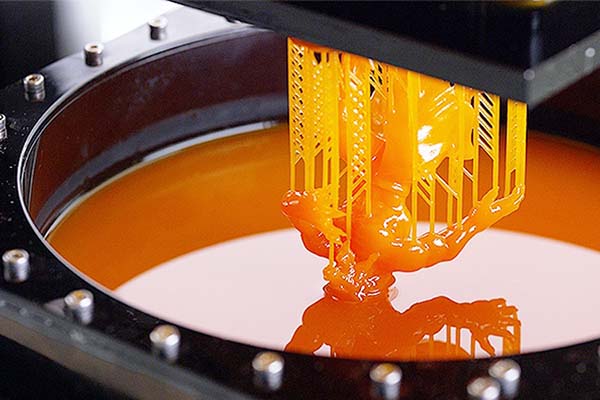

The Top 7 Ways to Make Rapid Prototypes

Rapid prototypes are an essential part of the product development journey. They are used for functional testing, proof-of-concept, sales demonstrations and as master models for casting and other manufacturing processes. There are now many rapid prototyping technologies available, both additive and subtractive. Here is a look at the seven most common and how they might […]

4 Great Ways to Find The Right Chinese Supplier

China is a great choice for product developers searching for new manufacturing suppliers. Along with its modern infrastructure, the Chinese industrial sector enjoys high levels of government support and there are factories able to produce almost any product you can imagine. However, not all suppliers are the same. It’s essential to find the right one […]

Product Applications Help You Find the Plastic That’s Right for You

When developing a new product, there are so many different types of plastic available to use. Choosing the right one depends on application-specific criteria. In our experience, developers should consider if the plastic material is food safe, impact resistant, flexible, engineering grade, fire retardant or biocompatible. The below are our recommendations on the most common […]