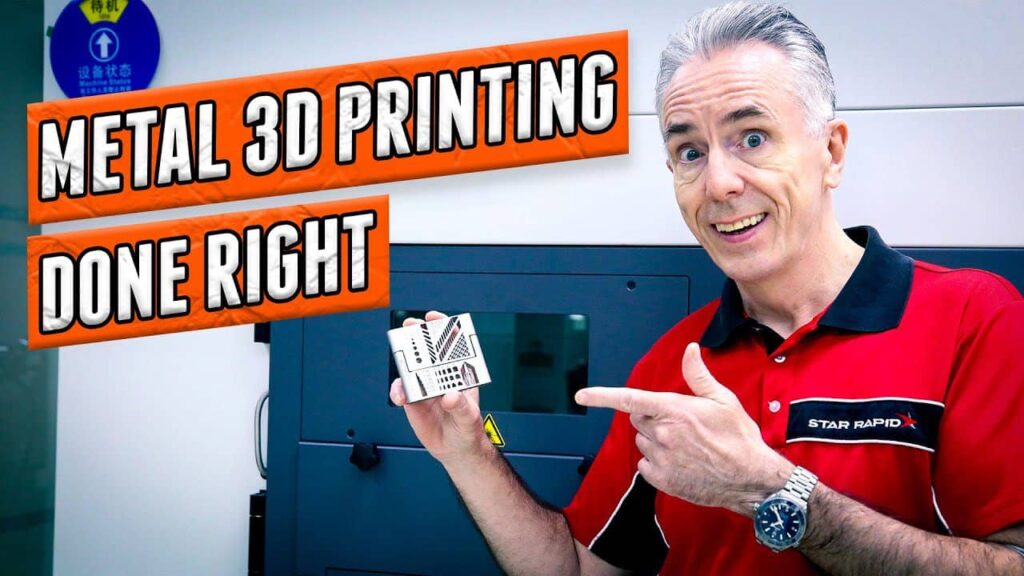

3DPrinting.com: “3D Printing Rekindles The Spirit of Invention”

Star Rapid’s CEO Jon Ross offers some insights on 3D printing and its ability to encourage people of all ages to get involved in the joy of making things again.

Choose The Right Plastic For Your Next Project

With thousands of plastics on the market, it can be a daunting task to decide which type is the best for your next rapid prototyping or low-volume manufacturing project. When choosing which plastic to use, there are going to be trade-offs between cost, moldability, surface finish, durability, strength and many others. The choice of plastic depends on […]

Industrial Equipment News: 7 Questions To Ask Yourself About Surface Finishes

What’s the best surface finish for your part? The answer to that question depends on having a clear understanding not only of what the product is expected to do but also the environment in which it will function.

What Tolerances Can You Expect When Manufacturing Prototypes And Low-Volume Production?

When you supply your 2D and 3D drawings for a quotation on a new project, you must specify the dimensions for critical areas on your parts, as well as the tolerance that you require. Very tight tolerances are neither practical nor desirable in most instances, so let’s look at the tolerances that we specify at Star Rapid for most projects, why we do that and what it means for your parts.

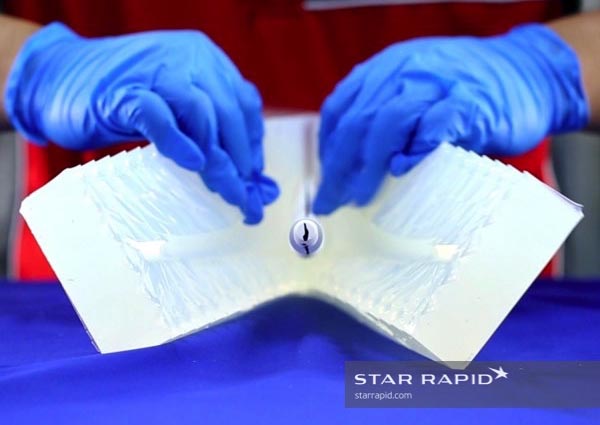

Marco Beverage Systems in Manufacturing Tomorrow Magazine

For the benefit of their readership, Manufacturing Tomorrow magazine recently talked with Gordon Styles about how we solved many engineering challenges and delivered a superior part to our clients.

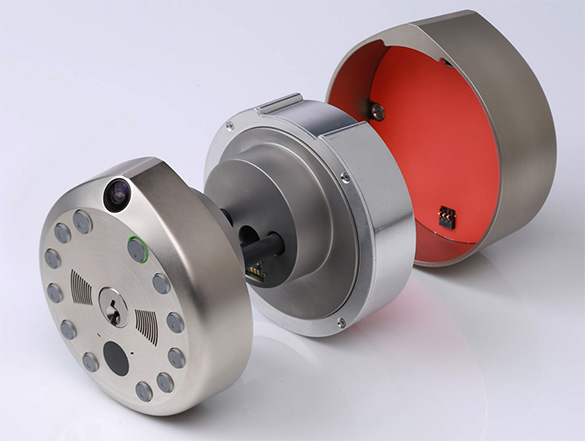

The Gate Camera Equipped Smart Lock In Design Engineer Magazine

This innovative security device has already received a good deal of attention from industry and tech watchers like Forbes and TechCrunch magazines. Now that case study is the subject of a separate article in Design World magazine.

How Can You Prevent Your Product From Being a Failure?

There’s a plethora of reasons for why new products fail. But there are different steps you can take to minimize the risks when developing a new product.

Successful Product Development: The Importance of Proof of Concept

You will be told that you need to prototype your product to make sure that it works. But before you dive into the world of rapid prototyping, there’s one step that quite a few startups miss out on: creating a proof of concept.

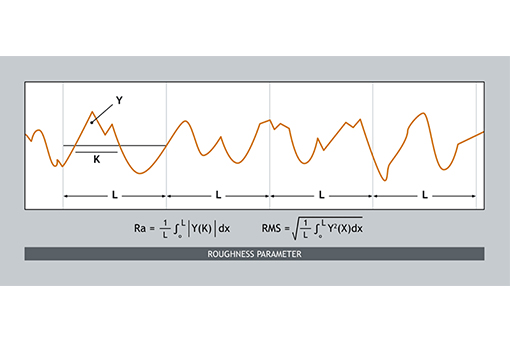

Understanding Surface Roughness for Product Development

Surface roughness is often described by the term Ra but many of our clients are unsure about what this means, how it’s measured and why it’s important to their product’s designs. So here we’d like to remove any mystery so you’re better able to specify exactly the type of surface roughness you want and need […]

What are the Top Passivation Techniques?

What Does Passivation Mean? Passivation means to alter the chemical structure of a metal at or just below the surface, so that it’s more stable and doesn’t want to react with other elements in an undesirable way. There are several different manufacturing processes that we routinely use to passivate the surface of a part. The […]