Why Small Dimensions Are A Big Deal in Manufacturing

Precision manufacturing means consistently producing parts that have dimensions with very fine tolerances, usually measured in microns or 10-6 meters. This is entirely possible when using good CAD/CAM digital equipment and modern, high-speed cutting tools. But there are some other practical considerations on the small scale that go beyond the equipment used, because all materials […]

Tips For Verifying A Supplier Remotely

As a product developer, you may be wondering how you can verify the integrity of your supply chain during these uncertain times, with so many quarantine and travel restrictions in place. While it may be difficult or even impossible to visit a supplier in person, there are still some things you can do to help […]

What Is A Coordinate Measuring Machine Used For?

One of the essential workhorses for product verification is our coordinate measuring machine. We use it every day to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about how this versatile machine is one more way we ensure every part we make meets and exceeds your expectations. What […]

The Micrometer, Its Parts, and Why It’s Essential for Making Quality Parts

What is a micrometer? A micrometer is a sensitive tool for making accurate measurements of linear dimensions. It’s one of the most important measuring instruments ever made. It has a rigid C-shaped frame. One side has an anvil that is fixed, and on the other side is a moveable spindle. The feature to be measured […]

Updating the Metric System to Improve Measurements of Mass

The original promise of the metric system was to connect all essential units of measurement (time, distance, force, etc.) to an unchanging natural law. To date, this has never been possible with mass, which was instead based on an object. Now, scientists may have finally found a way to conquer that challenge, eliminating a major […]

The Art of Inspecting Material

Manufacturing high-quality parts requires using high-quality material. Find out how Star Rapid tests all incoming material before manufacturing.

Testing and Measurement for 3D Prototypes

Read about how Star Rapid uses our advanced metrology equipment and techniques to verify raw materials and measure 3D prototypes in this recent article featured in Aerospace Manufacturing and Design. This publication is at the forefront in profiling the industry trends and business leaders driving innovation in this demanding field.

Weights, Measures And The Story Of The Kilogram

Star Rapid talks about the foundations of metrology and the special case of measuring how heavy something is. This lovely platinum/iridium cylinder is a kilogram. In fact, it’s the kilogram, as kept under very controlled conditions at the International Bureau of Standards near Paris, France. It forms the basis for the standard unit of mass, […]

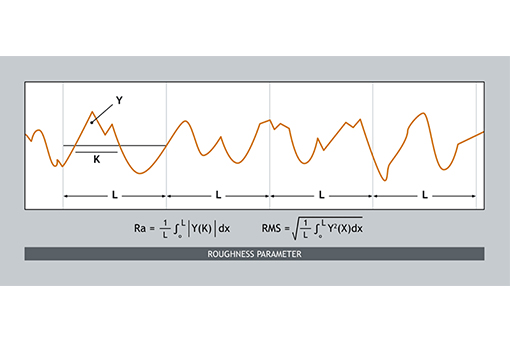

Understanding Surface Roughness for Product Development

Surface roughness is often described by the term Ra but many of our clients are unsure about what this means, how it’s measured and why it’s important to their product’s designs. So here we’d like to remove any mystery so you’re better able to specify exactly the type of surface roughness you want and need […]

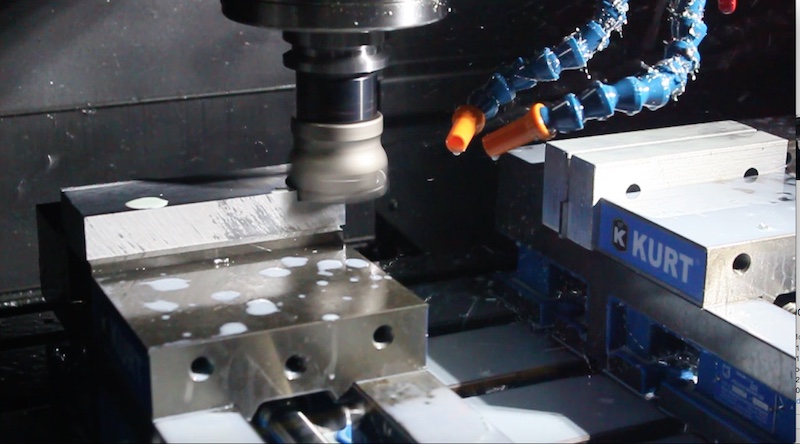

Making Surface Textures with Machine Tools

To get the right look and feel on your new product, you need to be able to not only define what kind of surface texture you want but also what technique you want us to use to create it. This will save time, money and frustration on your next project. Different techniques have different purposes, […]